Puretech Environmental is an effluent treatment plant company offering a full scale of effluent treatment services. We provide a full project management portfolio for effluent treatment plant that covers design, manufacture, installation, commissioning, performance guarantees and on-going maintenance services across the world. Puretech Environmental can address range of industrial pollutions, including pH, heavy metals, cyanides, and more. As effluent treatment experts, we love solving tricky problems for our customer. Our effluent treatment starts by understanding the manufacturing process, and then our team of professionals pick the right technology for the right problem to provide the client with a guarantee of performance.

Our design starts with a review of the data either provided by the client or ascertained via an understanding and an appreciation of the client’s manufacturing process.

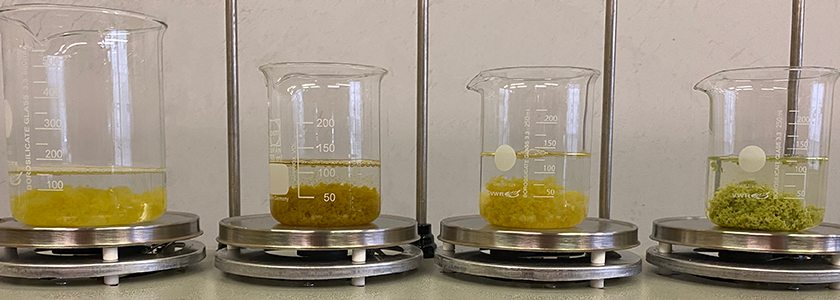

Should the effluent present unusual characteristic, lab trials and pilot tests can be carried out.

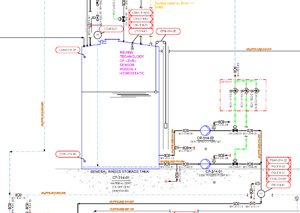

Once defined, the process is developed into a Piping & Instrumentation drawing, under AutoCad plant 3D which enables the production of a detailed Bill of Material.

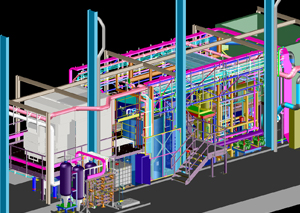

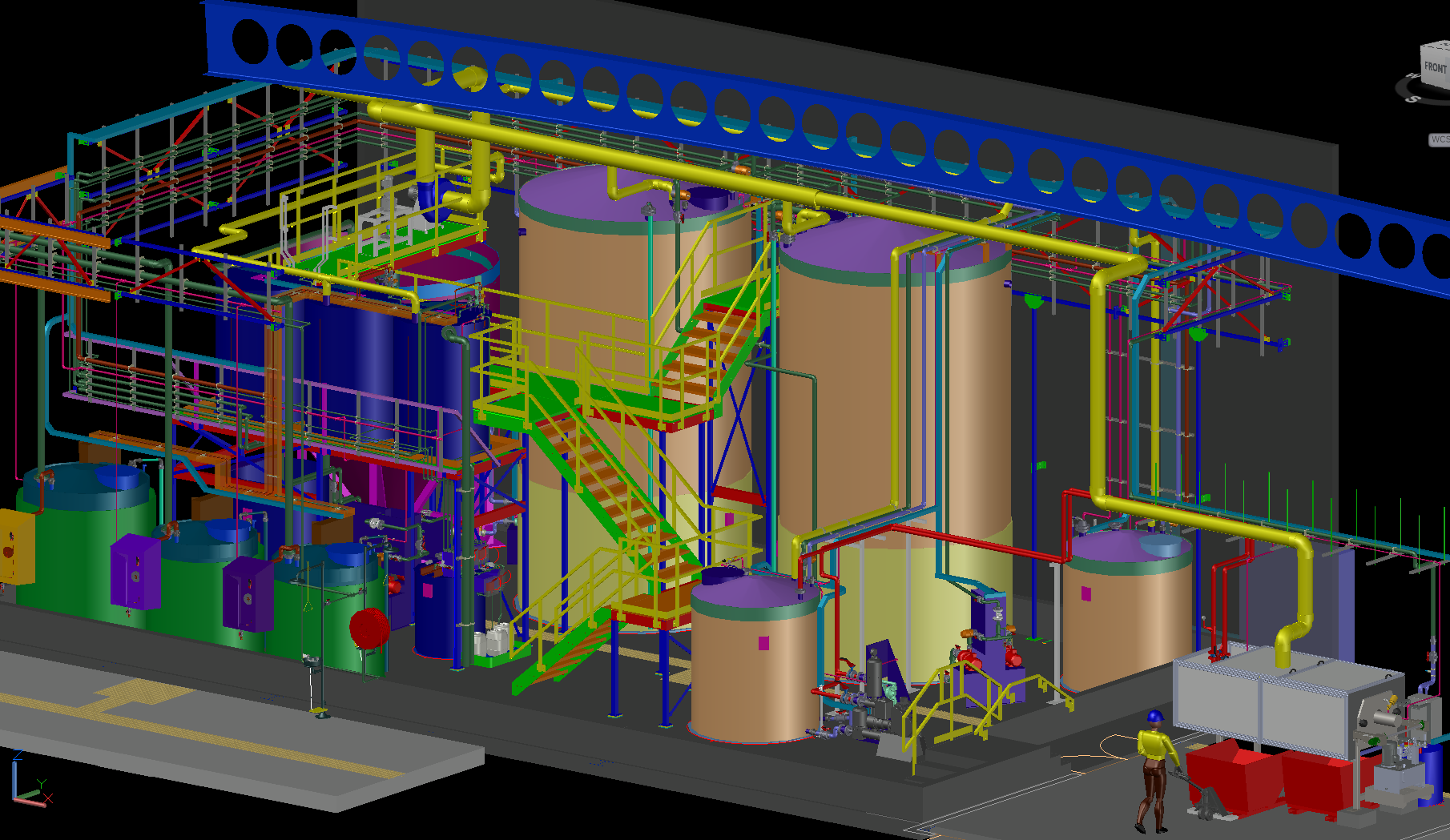

3D modelling of the plant is then produced, typically under Navisworks, so the operability and maintainability of the plant can be assessed and reviewed with the client.

A Functional Design Specifications is prepared to define the detailed automation operations and interlock of the proposed plant.

At this point a detailed review is carried out with the client typically through a Hazop Study which then enables a Design Freeze.

Detailed manufacturing drawings for the various equipment, tanks, platform are then produced, stress calculations carried out where necessary and pipework network are modelled up when facing multiple pumping stations into single or multiple streams.

ZF Automotive – Pontypool, manufactures 3 million plated brake parts per year.

The process plating plants and effluent treatment plant are critical to the site production.

Puretech Environmental Ltd’s expertise in design, supply and installation of a new effluent treatment plant improved site productivity, maintained legal compliance and generated savings.

They have an excellent site maintenance program and a remote support team - supplying technical operational advice, spares and fault rectification to reduce downtime.

Based on its own crew of skilled engineers, Puretech delivers any project size on a Turn-Key basis :

"Puretech Environmental have carried out numerous installation projects at our Washington Campus, each project was carried out to the highest standard. Their attention to detail along with their attitude towards Health and Safety makes them world class in their industry."

It is therefore the most crucial time where the consequences of all the previous steps are tested, validated, adjusted and tuned. Above and beyond a succession of equipment and technologies, we are providing a guarantee of performance.

All those skills are in-house and no sub-contractor are used at this stage.

Considering the broad spectrum of expertise, we are enrolling young engineers through apprenticeship scheme to ensure proficient engineer who can ensure our promise is being delivered!

Commissioning is also the opportunity for ensuring that all Hazop study actions are being closed out.

A commissioning report is being produced consigning all the settings and test carried out.

"Puretech Environmental came up with an original yet simple and efficient integrated design. The quality of our product has been enhanced. We are so pleased with it that we have awarded them the contract to install similar system for our Midlands' plant"

First of all our solution relies on a hard-wired point to point secure connection back to our own monitoring servers.

Secondly we are not physically linked to our client networks.

Thirdly the data are still primarily stored at our clients premises leaving them the total ownership of the solution.

Please contact us if you require further information and see how we can integrate your system onto our monitoring platform.

We pride ourselves in offering a responsive efficient technical support. Visit our support portal and contact us to judge by yourself.

Within the frame of maintenance contract we keep parts on the shelf ready to be dispatched within 24h or even same day week-end and bank holidays included.

"We are delighted by the quality of your services and appreciate your responsiveness and professionalism in supporting our needs and business. You are very reliable and quick to respond to any issues, your effective communication with technical support is second to none, your customer-based approach and professional approach both from you management/office team and engineers to deliver the service to keep our client satisfied is amazing delivery, thanks to this we have managed our client needs and not affect their business daily requirements."

THE PURETECH DIFFERENCE...:

... by the range of industrial pollutions we can address : pH, heavy metals, cyanides, hexavalent chromium, BOD, "Hard" COD, Fat Oil & Grease, suspended solids, sulphates, phosphorous, nitrates, Ammonia, and anything you can think of to challenge us.

THE PURETECH DIFFERENCE...:

... by picking the right technology for the right problem to provide the client with a guarantee of performance. Here are some of the processes we cover : Coagulation, Neutralisation, Flocculation, Oxidation, Reduction, Flotation, Settlement, Filter press, Screw press, Centrifuge, Ion exchange resin, Membranes technologies etc.

THE PURETECH DIFFERENCE...:

... Solving tricky problems for our customers is what gives us the edge and the enjoyment - We relish a challenge. Explore our case studies of previous projects