Puretech Environmental is an UK based effluent treatment plant company. The business was started by a team of effluent treatment experts in 2006, and has grown since then. We now provide a full project management portfolio for effluent treatment plant.

What makes us different is the range of industrial pollutions we can address. The pollutions covered include pH, Heavy metals, Cyanide, “Hard” COD (Chemical Oxygen Demand), BOD, NDT penetrant and emulsifier rinses, metal working fluids, organic pollution, suspended solids, temperature and more.

At Puretech Environmental, effluent treatment starts by understanding the manufacturing process which then enables the profiling of the effluent to be dealt with. Understanding the process also enables minimising the pollution at source in line with the philosophy of the IPPC legislation.

Contact Us

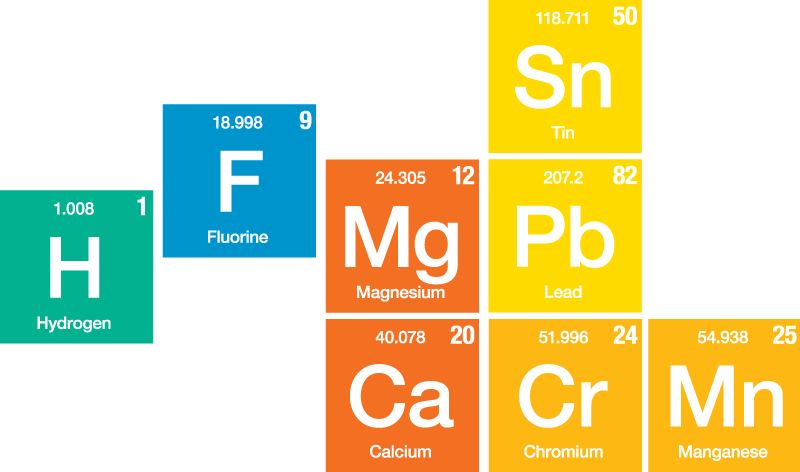

H+, hydronium ion which concentration is source of the acidity in water. Typically this acidity is to be neutralised with sodium hydroxide, lime or magnesium hydroxide but in some cases acid purification / recovery systems can be implemented. Puretech has a wealth of experience in dealing with a wide range of organic and inorganic acids used in the Industry (nitric, hydrofluoric, sulphuric, phosphoric, acetic etc.). We also offer complete solution for the storage and handling of those chemicals.

Magnesium, alongside calcium, is responsible for the hardness of the water. Typically this hardness is to be removed to produce soft water either of its own right or in preparation for reverse osmosis. This is achieved either by a softener operating on ion exchange or by addition of a calcium and magnesium sequestrant.

Chromium, widely used in the surface treatment industry and tanning industries, is often present in its hexavalent and most toxic state. Restricted under the REACH directive, Chromic acid, sodium dichromate are still in use. The treatment of hexavalent chromium is rather efficient using a reducing agent such as bisulphite or iron. Once converted to trivalent chromium it can be precipitated out of the effluent to reach level below 1ppm.

It forms the skeleton of the majority of organic compounds. Those organic compounds can be detrimental to the environment. They are typically identified by TOC (Total Organic Carbon), FOG (Fat oil and grease), HC (Hydrocarbon), or COD (Chemical Oxygen Demand – See Oxygen). Depending on their type, treatment processes include DAF (Dissolved Air flotation), Activated carbon, Ultrafiltration, Evaporation. In some cases of high concentration of biodegradable organics, Methanisation process can be implemented.

Whilst nitrogen gas (N2) is present at 80% in the air we breath, it can be found in many regulated pollutants : Nitrates, nitrites, ammonia, organic amines, cyanides etc. The “cleanest processes” would aim at either biologically treating the elements (e.g. nitrates, nitrites) in aerobic / anoxia environment or chemically oxidising the contaminants (Cyanides, ammonia, amines) using hydrogen peroxide or ozone with a catalyst (either photocatalytic or chemicals) to, ideally, release nitrogen as gas.

Phosphorous, present in mineral and organic compounds, mostly in its oxide form, whilst essential to life, any excess in the discharge effluent would hinder and develop detrimental species to the sewage plant or the environment. Depending on its form, Phosphorous can be very effectively removed with physico-chemical process (often with prior precipitation) or via biological digestion, providing it is within an acceptable ratio Carbon/Phosphorous

A conventional way of identifying the organic contamination is to measure the quantity of oxygen drawn by the effluent for its “ultimate” degradation : Chemical Oxygen Demand; or Biochemical Oxygen Demand which represents the quantity of oxygen required to bio-degrade (bacterial digestion) the contamination. The ratio BOD5/COD will provide a first approach estimation of the biodegradability of the effluent. Treatment processes based on aerobic digestion are : Activated sludge, Moving Bed Bio-Reactor (MBBR), Sequential Bio Reactor (SBR), Membrane Bio Reactor (MBR) or for contamination referred as “hard COD” : Photo-oxydation (H2O2/UV), Fenton reaction (H2O2/Fe2+), Ozonation.

Sulphur, when present as sulphide (S2-) is a toxic element which will be subject to low ppms limits. Usually found under oxygen deprived environment it can produce the potentially lethal H2S gas (rotten egg smell). Nowadays further emphasis is put on the oxide form commonly found as Sulphates (SO42-) which present a different challenge as it is widely used in the industry and has a high solubility limit with most cations. Puretech Env. has developed a couple of processes either based on ion exchange or precipitation to enable the plant to achieve levels as low as 100ppm.

According to the Pauling scale Fluoride is the most electronegative element. It is therefore searching for the most electro-positive element to form the strongest possible ionic bond. Often found in effluent from factories using hydrofluoric acid, the removal of fluoride is typically achieved by precipitation using calcium (sometimes with the implementation of a high sludge density process). Low limits can be achieved by selective removal using weak acid cation resin doped with aluminium.

THE PURETECH DIFFERENCE: ... by the range of industrial pollutions we can address : pH, heavy metals, cyanides, hexavalent chromium, BOD, "Hard" COD, Fat Oil & Grease, suspended solids, sulphates, phosphorous, nitrates, Ammonia, and anything you can think of to challenge us...

THE PURETECH DIFFERENCE...:

... by the range of industrial pollutions we can address : pH, heavy metals, cyanides, hexavalent chromium, BOD, "Hard" COD, Fat Oil & Grease, suspended solids, sulphates, phosphorous, nitrates, Ammonia, and anything you can think of to challenge us.

THE PURETECH DIFFERENCE...:

... by picking the right technology for the right problem to provide the client with a guarantee of performance. Here are some of the processes we cover : Coagulation, Neutralisation, Flocculation, Oxidation, Reduction, Flotation, Settlement, Filter press, Screw press, Centrifuge, Ion exchange resin, Membranes technologies etc.

THE PURETECH DIFFERENCE...:

... Solving tricky problems for our customers is what gives us the edge and the enjoyment - We relish a challenge. Explore our case studies of previous projects