Enhanced oxidation is the use of highly reactive oxidising reagents.

Oxidation is used to treat effluent in many applications, for example :

Whilst the above examples have been achieved using sodium hypochlorite (bleach), the destruction of the so called ” hard COD” (i.e. non easily biodegradable COD) is achieved using stronger reagents. The “power” of an oxidsing agent is expressed by its ORP (Oxydo-Reduction Potential).

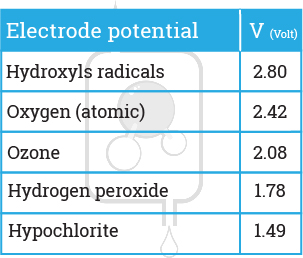

In the below table, we have the value for stronger reagents such as Hydrogen peroxide and Ozone :

Redox potentials of some oxidising species

In fact, whether we use hydrogen peroxide with a catalyst (such as ferrous ion (Fenton Process) or UVc), or Ozone it is the generation of the highly reactive, extremely short lived (~nanosecond), hydroxyl radicals OH• we are after. Those have the power of breaking covalent bonds that other treatment would not touch

Whilst the storage and handling of those reagents present their own challenges, the reaction by-products are more environmentally friendly.

Contact Us

ZF Automotive – Pontypool, manufactures 3 million plated brake parts per year.

The process plating plants and effluent treatment plant are critical to the site production.

Puretech Environmental Ltd’s expertise in design, supply and installation of a new effluent treatment plant improved site productivity, maintained legal compliance and generated savings.

They have an excellent site maintenance program and a remote support team - supplying technical operational advice, spares and fault rectification to reduce downtime.