The main challenge was the hazard management involved in the storage and distribution of hydrofluoric acid 30%, nitric acid 70%, potassium fluoride 20%, sodium hydroxide 20%.

After several stages of HazOp studies, Puretech Env. developed a plant where every chemical is now stored in a double skin tank (volume from 2 to 7 m3), installed in a bunded area. Transfer from decanting cabinets to the tanks and from tanks to the process lines is done by using double skin pipes (PVDF, PP and HDPE were used). Pumps and all single skin equipment have been installed in a locked plastic enclosure. Acid scrubbers connected to the vessel vents trap the acidic fumes coming from the tanks. Leak sensors have been installed in the bunds, outer pipes and cabinets.

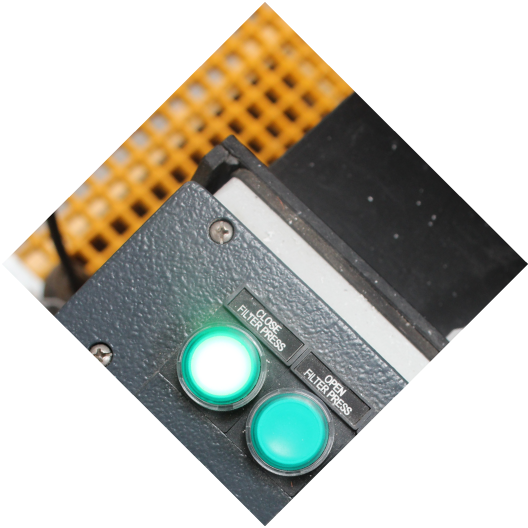

200 safety and operational alarms have been programmed, segregated into 3 priority groups of which the operators, site security and management can choose how and when to send to the duty operators. These alarms are also sent to our server as part of a maintenance contract.

The above setup now forms our standard alarm management system.

"Puretech Environmental have carried out numerous installation projects at our Washington Campus, each project was carried out to the highest standard. Their attention to detail along with their attitude towards Health and Safety makes them world class in their industry."