Flocculants can be used in various forms (powder, liquid emulsion or liquid at lower concentration ready to use). Several criteria’s define a polyelectrolyte : Molecular weight, polymer structure and ionic charge. Below is the range of application according to ionic charges.

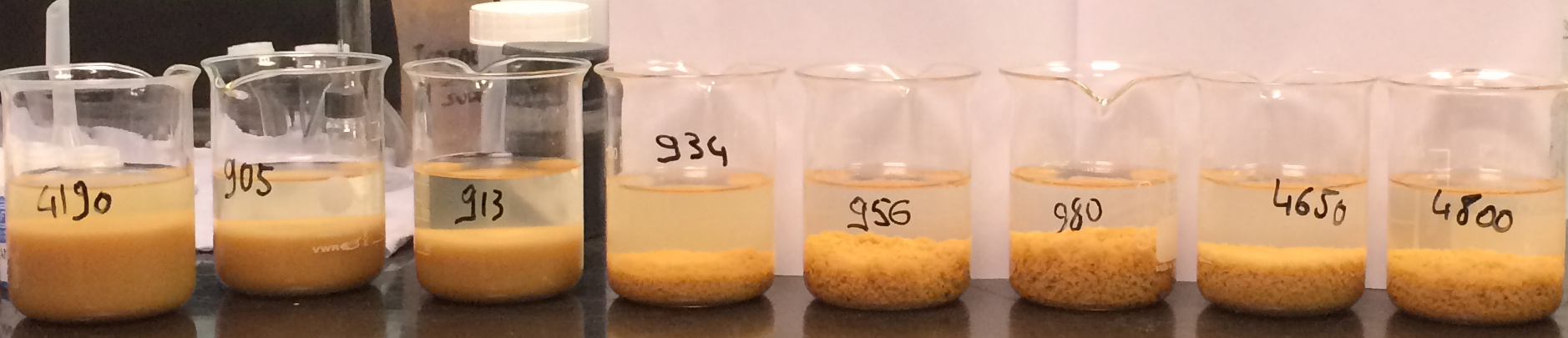

There is a wide range of polyelectrolyte and in order to determine the right combination between flocculant type and dosing rate, jar-tests are performed in the lab with the customer’s effluent checking for the reaction time, flocs size, quality of clarification and floc resistance. Refer to our technical article on how to conduct a jar test found in our support portal if you want to carry out your own!

Do not hesitate to contact for further assistance. As we work directly with manufacturers of polyelectrolyte, we have access to a great range of polyelectrolytes.

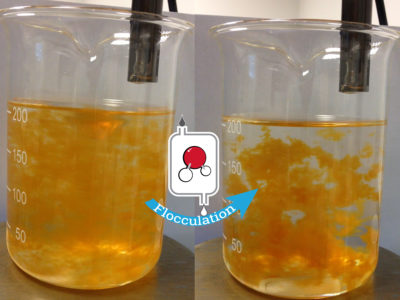

Flocculation step is done under slow agitation or in a flocculation tube to allow the particles to be quickly and easily separated from the water, either by settlement or by flotation.

Once clarification has been obtained during flocculation, the sludge can subject to further addition of an other polyelectrolyte which may have a different structure to improve dewatering process on centrifuge, screw press or filter press.

"We are delighted by the quality of your services and appreciate your responsiveness and professionalism in supporting our needs and business. You are very reliable and quick to respond to any issues, your effective communication with technical support is second to none, your customer-based approach and professional approach both from you management/office team and engineers to deliver the service to keep our client satisfied is amazing delivery, thanks to this we have managed our client needs and not affect their business daily requirements."