The main challenge was the wide range of consented elements on the trade effluent agreement: chlorides, sulphates, nitrates, phosphorus, zinc, nickel, copper, aluminium, chromium, surfactant, COD and TSS. Added to this, Thermo-King corporate policy required Puretech Environmental to guarantee half the allowed limit values!

Due to the above large number of consented ion and the predominantly alkaline nature of the incoming effluent, Puretech developed the treatment process using carbonic acid transferred to the effluent using fine bubble diffusing membranes.

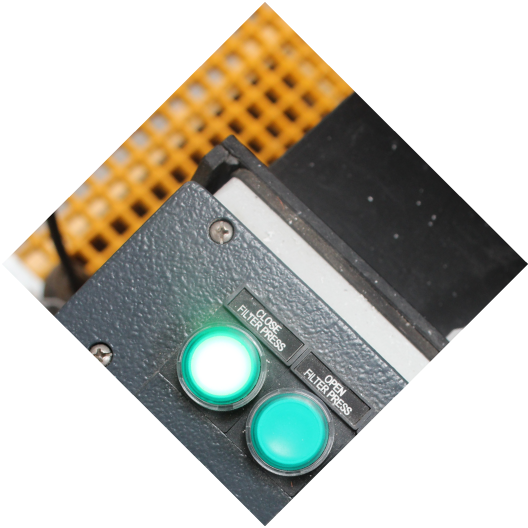

Each effluent stream (general rinses, spent acids, spent alkalis) of the process line is sent to its own storage tank. A first treatment is performed in the spent alkalis tank with a primary neutralization. Then, a few specific blends of these streams are treated on a 25m3 batch reactor where coagulation, neutralization, metals insolubilisation, flocculation and settlement are performed.

The plant has been operational for 2 years with 100% compliance and is even processing 30% more effluent than the original design.

"I would highly recommend Puretech Environmental as they provide excellent solutions, service and are always available to help you. The people are very well skilled and passionate about what they do, and this is clearly seen in their work - Five start rating"