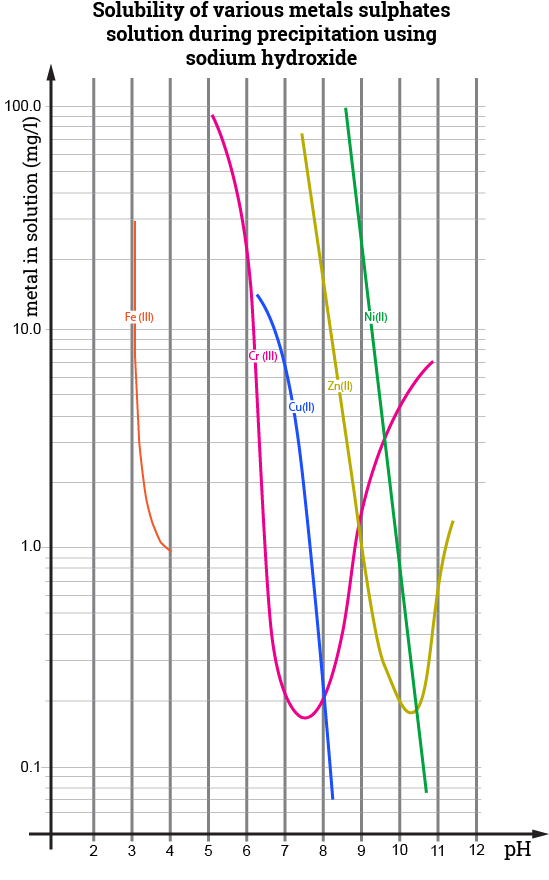

Most commonly the precipitation of heavy metals (Chromium, Zinc, Nickel, Copper, Tin, Iron, Aluminium) is achieved by adjusting the pH to ensure the precipitation as metal hydroxides.

In some instances, the metals remains in solution as it is in a complexed form which often keeps the element over the discharge limits. In that case, we case either implement a specific destruction of the organic complex or add an insolubilising agent which can have a greater affinity with the element that we are trying to remove and present the advantage to then become insoluble.

As well as the metals, we use precipitation techniques to ensure sulphates & phosphates removal.

Also COD can be reduced when it is generated by an organic molecules which can be converted into one of its insoluble form (e.g. tartrates, citrates etc.).

Once precipitation has been achieved, it is usually followed by flocculation.

Contact Us

ZF Automotive – Pontypool, manufactures 3 million plated brake parts per year.

The process plating plants and effluent treatment plant are critical to the site production.

Puretech Environmental Ltd’s expertise in design, supply and installation of a new effluent treatment plant improved site productivity, maintained legal compliance and generated savings.

They have an excellent site maintenance program and a remote support team - supplying technical operational advice, spares and fault rectification to reduce downtime.