In 2017, GKN Aerospace in Bristol wanted to convert their chromic anodising line into a Tartaric Sulphuric Anodising line (TSA) as per the REACH directive requirement.

The design of a recycling system operating on tartrates, which have a tendency of favouring fungus growth, coupled with a strict discharge limit on sulphates, posed specific challenges.

The new process line comprises 3 recycled rinse tanks, each fed with 12 m3/h of deionised water. In order to achieve this goal, Puretech designed and installed 2 separate recycling systems based on ion exchange resin, operating in duty/stand-by. Each system has a 36m³/h capacity.

Rinse water is firstly pre-treated via a fine filtration filter followed by UV sterilization and finer filtration to limit fungus development in the resin vessels or in the process tanks.

The recycling system is composed of 3 types of ion exchange resin : Strong acid cation, Weak base anion and Strong base anion.

To control the possible microbial growth in the resin, a specific automatic shock disinfection, using peracetic acid has been programmed.

The Airbus TSA specification, which GKN is required to follow, also required a pH monitoring of the DI water. We implemented our specific setup for in-line pH monitoring of DI water. The water is then returned to the recycled rinses.

When the conductivity of the recycled water exceeds 10μS/cm the unit carries out a regeneration process which might include the peracetic disinfection. The stand-by unit then goes on duty.

The regeneration is carried out using hydrochloric acid and sodium hydroxide . The regenerant is directed to a dedicated buffer tank and is then processed through a batch reactor.

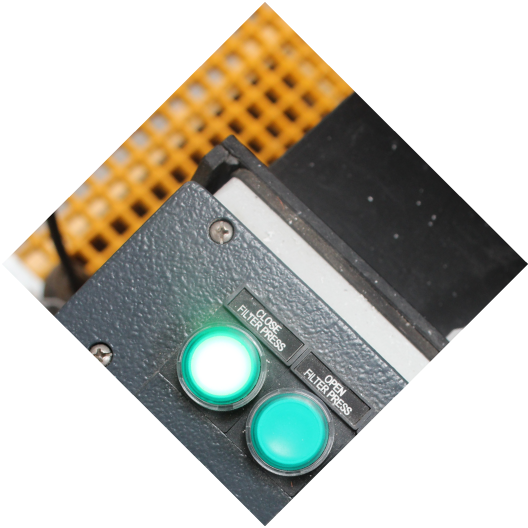

All treatment steps are performed in the same reactor including coagulation, sulphates and tartrates precipitation, flocculation and settlement. Analysis are performed on the treated water, recorded on the control system before any water can be discharged. Settled sludge is extracted from the bottom of the reaction vessel and dewatered on a filter press.

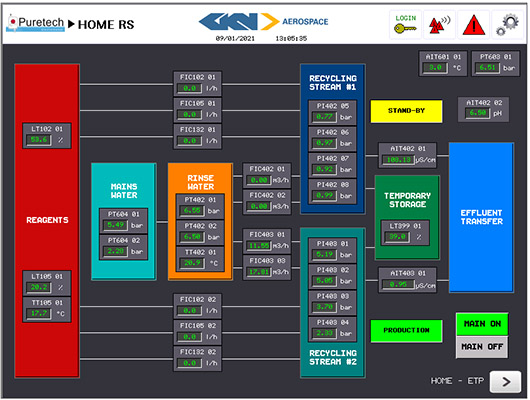

SCADA – Recycling system

A fibre network has been implemented, to ensure interlocking between effluent plant and recycling plant operations.

"Puretech Environmental have carried out numerous installation projects at our Washington Campus, each project was carried out to the highest standard. Their attention to detail along with their attitude towards Health and Safety makes them world class in their industry."