The effluent is generated from plating on connectors with elements such as Nickel, Tin, Gold and Silver with all their associated pre-treatment. At the time, Harwin was using 10m3/h of water and the trade effluent agreement was to be reviewed.

Recycling on Ion exchange resin

Because it precipitates at a low pH and would eventually clog a conventional recycling system, Puretech Env. developed a solution for the selective removal of tin. The core process of the implemented solution is a water recycling system based on macroporous ion exchange resin operating at 10m3/h.

Two waste streams are generated from the new plant :

Those two streams are processed through a single batch reactor which offers versatility and supreme control over the discharge.

In this batch reactor, a physico-chemical process is carried out based on coagulation, precipitation, flocculation, bivalent metal insolubilisation and settlement.

Water recycling and effluent treatment plant at Harwin

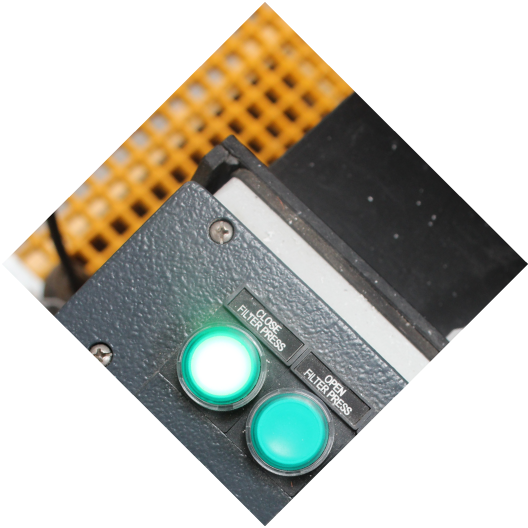

At the end of the treatment, the operator has the opportunity to analyse the treated water prior to authorising its release via a sand filter.

Coupled with a re-arrangement of the rinse structures and an adequate stream segregation, Harwin is now discharging only 10m3 per week as opposed to 10m3 per hour and has enjoyed a 100% compliance with the new trade effluent agreement.

The other significant added benefit of such water recycling is the rinse water is returned to the plating plant at a conductivity below 5μS/cm.

"Puretech Environmental have carried out numerous installation projects at our Washington Campus, each project was carried out to the highest standard. Their attention to detail along with their attitude towards Health and Safety makes them world class in their industry."