In 2012, McQuillan Envirocare, a large waste management company based in Northern Ireland invested in a waste chemical treatment facility which aim was to process liquid waste on site. The obvious challenge of such project is the wide spectrum of waste to be dealt with : Organic and inorganic waste, strong acid and bases and waste metal working fluid.

It was critical to offer McQuillan a highly versatile plant which would lend itself well to the typical handling of liquid on a waste management site (control of recipes, multiple possible connections, direct truck off loads etc.).

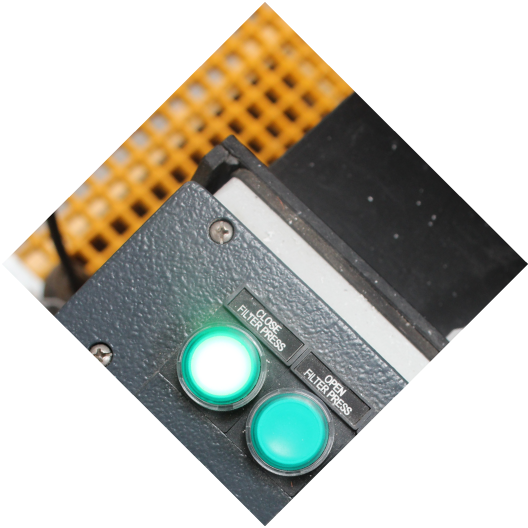

Developed in close co-operation with the client design team, the plant comprises of two batch reactors (5 and 15m3), a vacuum evaporator for the handling of the most concentrated waste and a filter press operating at 15 bar. Several buffer tanks are used according to the type of waste to be contained, and 6 IBC bunded stations have been provided for the emptying of this common and useful means of bulk transfer.

Regulated by the Environment Agency, it is critical for McQuillan to ensure that a breach is not physically possible so secondary and tertiary containment together with its management were implemented and controlled via the control system we designed and built for them.

McQuillan is an other of our little success story of a plant supported by one of our maintenance contract and in 2018 we designed and built a third batch treatment facility (25m3).

Batch reactors